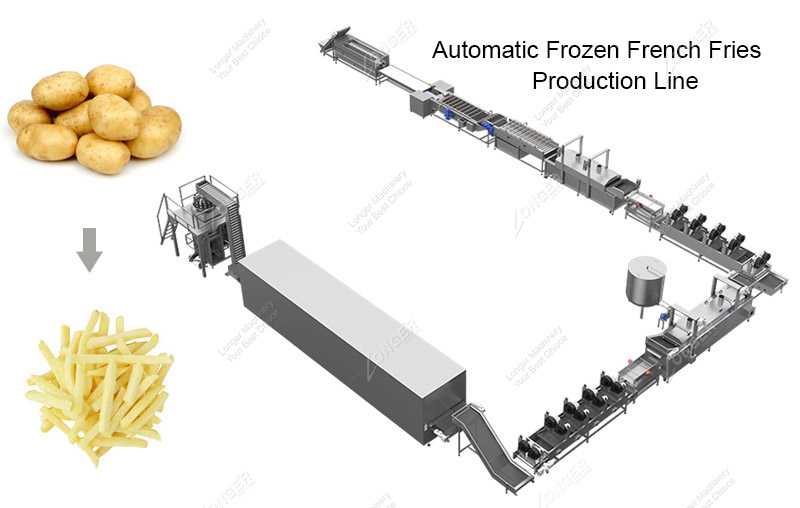

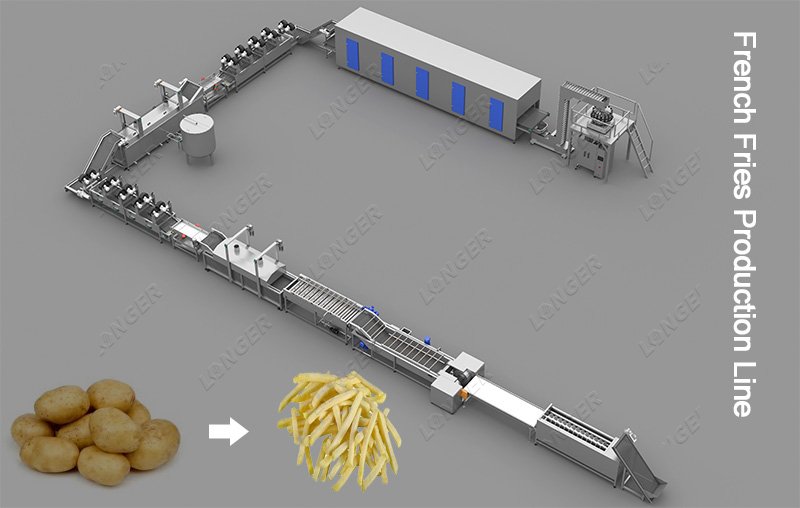

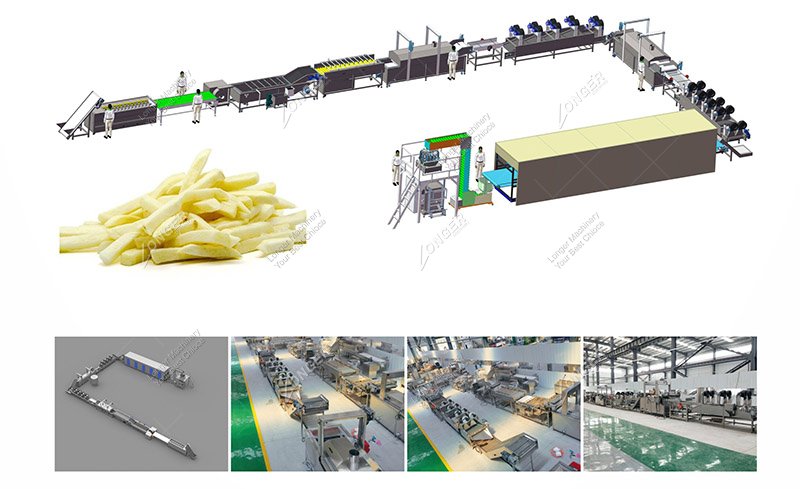

Automatic Frozen French Fries Production Line Introduction

This whole set turnkey production line is used to clean and peel fresh potatoes and process them into flat slices, wavy slices or strips with different cutting machine. The processed potato French fries are blanched, drained, fried and seasoned to become crispy and delicious potato chips or French fries.

Different french fries production line capacity for selection, such as 200kg/h, 300 kg/h, 500kg/h, and 1 ton/h, 2 ton/h, etc. support customization.

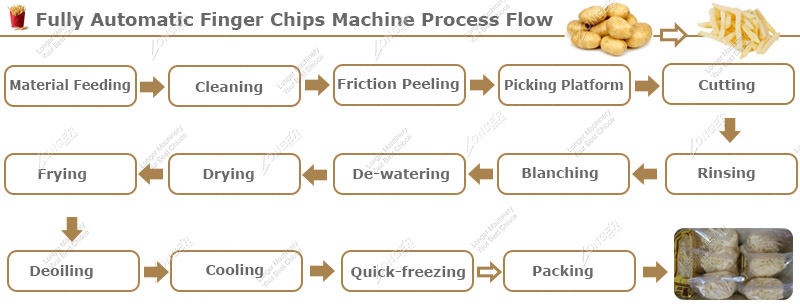

Frozen French Fries Manufacturing Process

- Potatoes Peeling: Potatoes are first washed and peeled by a potato cleaning and peeling machine.

- French Fries Cutting: The peeled potatoes are cut into potato fries by high speed potato cutting machine.

- Rinsing: French fries into the rinsing and rinse the mucus on the surface.

- Blanching: Blanching for passivate the oxidase in the fries, prevent color deterioration, and speed up dehydration.

- Dewatering: The fries after blanching enter dewatering machine to remove excess water.

- Frying: The fries after dewatering are sent to the french fries fryer by the lifting conveyor for frying treatment.

- De-oiling: The fried fries are drained by the air-dried lifter and then sent to next stage for seasoning.

- Mixing: Seasoning machine is equipped with automatic powder feeding device, which can adjust the amount of powder feeding and fully mix the fries and seasoning powder.

- Automatic production to manufacture frozen French fries from fresh potatoes

- Machines of this whole line are made of high quality stainless steel 304, meets food production requirement

- Voltage can be customized, like 220v/380v

- Size of French fries ranges from 2-10 mm, can be adjusted

- Equiped with advanced heating system,save energy cost

- Suppot customization, like production layout, capacity, etc.

| Product Name | Frozen French Fries Production Line |

| Final Product | Fozen French Fries |

| Raw Material | Fresh potatoes |

| Capacity | 200 kg/h |

| Working Shop | >300m2, height>4m |

| Voltage | 380/50Hz/3Phase |

| Power | 250kw(Customized) |

| Workers | 6-8 workers |

| Heating | Gas(Can be customized electricity) |

1, How much is the machine cost? Answer: Different models have different price, just tell us your requirement, our sale will suggest you suitable model and price. 2, What is the raw material of your machine? Answer: Our machines are made of stainless steel material, if you have special requirement for the machine, just feel free to tell us. 3, What if the voltage can't fit our country? Answer: The voltage can be customized, just tell us before the machine is made. 4, For the frying machine, which heating way is better? Answer: Dear, we have gas heating and electric heating, also can be customized. You can choose the suitable one according to your need.