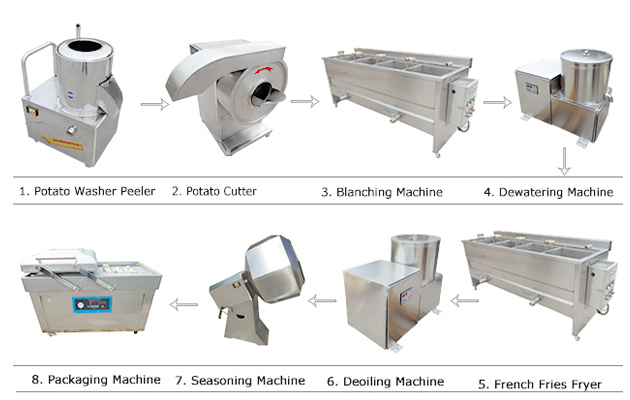

Whole Set Semi Automatic French Fries Making Machine

Relying on advanced technology, sophisticated processing and testing equipment, reliable manufacturing quality, strict quality assurance system and perfect after-sale service, sincerely welcome customers at home and abroad to our company, visit, to discuss cooperation.

Manufacturing Process for French Fries Production

- Potato washing peeling machine: Adopt corundum lined with cleaning peeling machine or brush type cleaning machine, can finish the work of cleaning and peeling, high efficiency with low loss.

- French fries cutter machine: Can slice or cut potatoes into slices or strips. Slice thickness, cutting size can adjust at will.

- French fries blanching machine: Blanch the cut potato chips or French fries for protecting color.

- Centrifugal deoiling machine adopts centrifugal dehydration, which can greatly shorten the frying time, improve the French fries taste. Improve the production efficiency and reduce the cost of production.

- French fries fryer machine: Advanced frying machine, uses oil water mixture technology, accurate oil temperature control, thus ensure the quality of the French fries taste. Finishing working, release water, residue will flow out together with water.

- Deoiling machine: Centrifugal deoiling machine overcomes the disvantages of high oil content and greasy mouth for french fries, to improve the taste of French fries.

If you want large production capacity or automatic production, you can consider factory automatic French fries production line.

| No. |

Name

|

Power |

Dimension

(mm) |

Output (kg/h) |

| 1 |

Potato Cleaner Peeler

|

1.5kw

|

1600*730*840 |

800

|

| 2 |

Potato Cutting Machine

|

1.1kw

|

950*900*1000

|

700

|

| 3 |

Blanching Machine

|

24kw

|

1000*500*800

|

500

|

| 4 | Centrifugal Dehydrator |

1.5kw

|

1000*500*850

|

500

|

| 5 |

French Fries Fryer

|

36kw

|

500*500*900

|

100 |

| 6 |

Deoiling machine

|

1.5kw

|

1000*600*850

|

700

|

| 7 |

Flavoring machine

|

1.1kw

|

1100*800*1300

|

600

|

1, How much is the machine cost? Answer: Different models have different price, just tell us your requirement, our sale will suggest you suitable model and price. 2, What is the raw material of your machine? Answer: Our machines are made of stainless steel material, if you have special requirement for the machine, just feel free to tell us. 3, What if the voltage can't fit our country? Answer: The voltage can be customized, just tell us before the machine is made. 4, For the frying machine, which heating way is better? Answer: Dear, we have gas heating and electric heating, also can be customized. You can choose the suitable one according to your need.